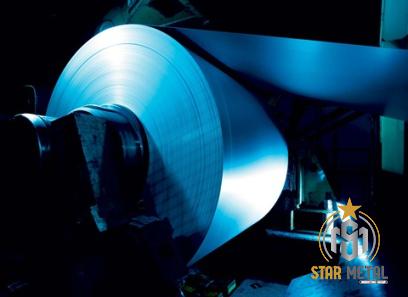

In the ever-evolving landscape of the industrial world, one material has consistently held a pivotal role in shaping the infrastructure and manufacturing sectors: LME steel HRC. This distinguished product, known for its exceptional properties and versatile applications, has become a cornerstone in the production of a wide array of goods and structures.

From towering skyscrapers to intricate machinery, LME steel HRC has proven itself as a reliable and indispensable material for modern construction and manufacturing processes.

.

Furthermore, LME steel HRC exhibits remarkable corrosion resistance, thanks to its protective oxide layer that forms on the surface of the material.

Furthermore, LME steel HRC exhibits remarkable corrosion resistance, thanks to its protective oxide layer that forms on the surface of the material.

This layer acts as a barrier against environmental factors such as moisture, chemicals, and abrasion, helping to prolong the lifespan of the steel and maintain its appearance over time.

This anti-corrosive property is especially beneficial in outdoor applications where exposure to the elements could otherwise compromise the integrity of the structure or component.

By opting for LME steel HRC, manufacturers can ensure the longevity and durability of their products, even in challenging environments.

Another notable advantage of LME steel HRC is its recyclability and sustainability.

As a highly recyclable material, steel can be repurposed and reused multiple times without losing its inherent properties.

This not only reduces the demand for new raw materials but also minimizes waste and environmental impact associated with manufacturing processes.

By choosing LME steel HRC, businesses can contribute to a more sustainable and eco-friendly production cycle, aligning with global efforts to reduce carbon footprint and promote resource conservation.

..

Similarly, in the aerospace sector, LME steel HRC plays a critical role in the fabrication of aircraft structures, landing gear, and engine components.

Similarly, in the aerospace sector, LME steel HRC plays a critical role in the fabrication of aircraft structures, landing gear, and engine components.

The material’s combination of strength, lightweight, and corrosion resistance makes it well-suited for aerospace applications where reliability, performance, and safety are paramount.

Aerospace engineers value LME steel HRC for its ability to withstand extreme conditions, such as high altitudes, rapid temperature changes, and aerodynamic forces, without compromising structural integrity or performance.

In the energy industry, LME steel HRC is utilized in the production of power plants, pipelines, and renewable energy infrastructure.

Its high tensile strength and corrosion resistance make it an ideal material for withstanding harsh operating conditions in power generation facilities.

Whether used in coal-fired plants, nuclear reactors, or wind turbine components, LME steel HRC provides the durability and longevity needed to ensure the efficient and reliable supply of energy to communities around the world.

…

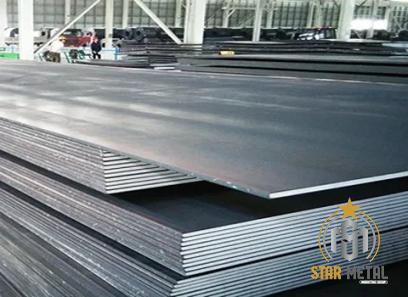

In conclusion, LME steel HRC represents a cornerstone material in the modern industrial landscape, offering unparalleled strength, formability, corrosion resistance, and recyclability across a diverse range of applications.

In conclusion, LME steel HRC represents a cornerstone material in the modern industrial landscape, offering unparalleled strength, formability, corrosion resistance, and recyclability across a diverse range of applications.

Its versatility and performance advantages make it a preferred choice for businesses seeking to enhance product quality, durability, and sustainability in construction, manufacturing, automotive, aerospace, energy, and infrastructure development.

Embrace the possibilities of LME steel HRC and unlock a world of innovation, reliability, and success in your industry.

Your comment submitted.