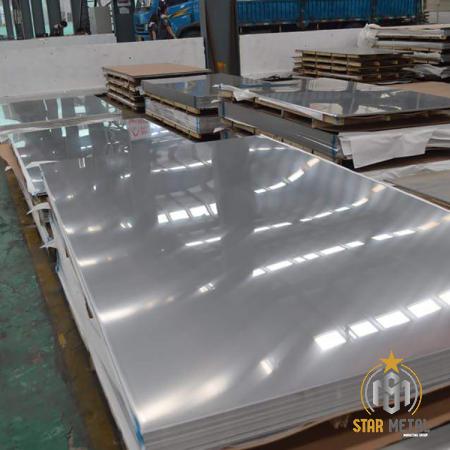

Soft steel slabs are in fact one of the highest quality slabs in Iran, which is usually used in its production and manufacturing process, and quality raw materials to satisfy all buyers, customers, and industries. Types of steel slabs are offered in different sizes in the world market and usually, buyers can buy these goods according to their needs and use them in different professions. Contact us through our website to get more information about the selling price of various types of steel furniture.

The Difference between Mild Steel and Galvanized Steel

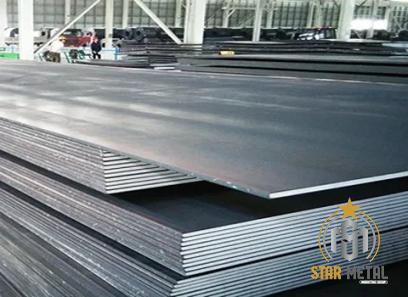

Mild steel will rust very hard, while galvanized iron has corrosion resistance. Mild steel is a type of carbon steel that is an alloy of iron and carbon with some trace elements. The cost of this type of steel is low. In addition, it has many desirable properties for many applications. Due to its low carbon content, mild steel is softer than other forms of carbon steel. Also, the strength of this steel is low. These properties of mild steel have some additional features, such as high flexibility and high flexibility.

Mild steel has low tensile strength. However, it is cheap and easy to produce. Carbon is useful for increasing the hardness of steel surfaces. It is a heat treatment process in which steel absorbs carbon from its surroundings (coal or carbon monoxide must be present) when the steel is heated. The high amount of iron in mild steel causes it to become magnetic. But if the steel does not have a good coating, it rusts easily. It is galvanized iron or steel that has a protective coating, a coating on the steel surface, to prevent rust.

It is interesting to know that the types of steel slabs are very different from each other in terms of company name and manufacturer brand, and in the target markets, based on this parameter, they receive various prices. In a way that in the market at present the best types of steel slabs are introduced in Iranian samples and compared to samples imported from other countries, it has a higher quality.

Explanation Of Continuous Casting Of Steel Slabs

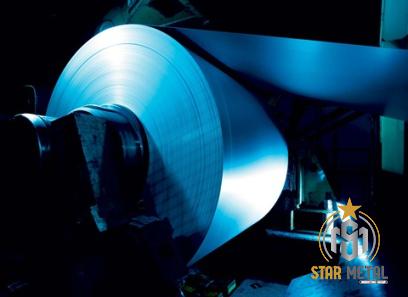

Continuous casting is a continuous casting process in which all the steps of melting until final cooling and production of semi-finished sections of bloom, billet, and slab in it, in a continuous set called CCM or casting machine and it is done continuously. The metal sections produced in this machine are subjected to forming operations such as rolling, forging, extrusion, etc. To be converted into consumable products such as sheets, pipes, profiles, wires, rebars, etc.

Continuous casting is a continuous casting process in which all the steps of melting until final cooling and production of semi-finished sections of bloom, billet, and slab in it, in a continuous set called CCM or casting machine and it is done continuously. The metal sections produced in this machine are subjected to forming operations such as rolling, forging, extrusion, etc. To be converted into consumable products such as sheets, pipes, profiles, wires, rebars, etc.

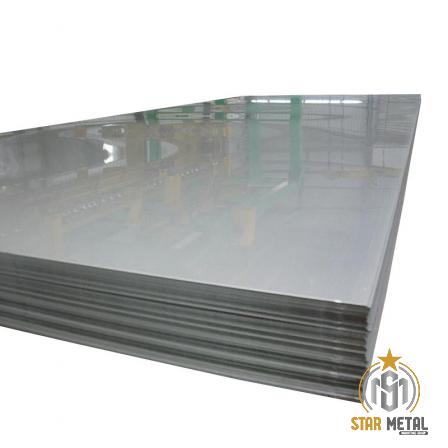

The slab is an ingot that usually has a rectangular cross-section, its width is at least twice its thickness and sometimes up to 12 times. The cross-section of the slab is more than 100 square centimeters and its length is up to 12 meters. Slabs are produced either directly from continuous casting or indirectly from hot-rolled ingots. Slabs are used to make flat products such as sheets and coils or pipes and tubes. These types of slabs have a lot of differences based on the type of production processes in terms of quality and finally in terms of price that each of the applicants of this type of product buys based on their budget.

Producer of Steel Slab for Buy

Iran is one of the largest producers of great steel slabs, which produces the highest quality of this product in factories and is mainly supplied all over the world. In this collection, we offer different types of high quality steel slabs at an affordable price to you, the buyers, and our only effort is to meet your needs and satisfy you, to expand our sales market. Our supply is also done online, in which our online sales consultants are ready to serve you at any time and guide you in any field and announce steel slab prices instantly.

Iran is one of the largest producers of great steel slabs, which produces the highest quality of this product in factories and is mainly supplied all over the world. In this collection, we offer different types of high quality steel slabs at an affordable price to you, the buyers, and our only effort is to meet your needs and satisfy you, to expand our sales market. Our supply is also done online, in which our online sales consultants are ready to serve you at any time and guide you in any field and announce steel slab prices instantly.

Your comment submitted.