Outstanding direct reduced iron at the best price is offered to buyers through reputable agencies and the distributors have made every effort to be able to deliver the country’s domestic products to customers in the best way, to date, they have achieved success in this field. Today, sellers with direct reduced iron sales on this site have been able to gain many customers and orders daily.

The Direct Reduced Iron Process

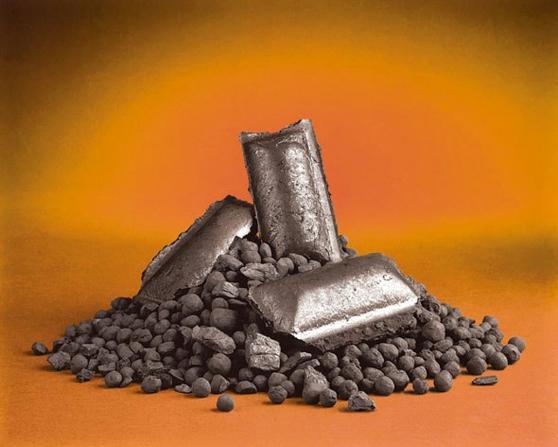

The direct reduced iron process is such that it usually contains more than 90% of metallic iron which tends to combine with oxygen to produce reduction iron, impurities such as oxygen must be removed from the iron ore by chemical reduction. There are different methods for producing iron most of this production is done by the blast furnace process and as a reducing agent after entering the furnace through processes and has carbon in the form of molten iron outside which eventually this molten iron is converted into steel. Iron production process by blast furnace in terms of production rate; it has high efficiency, but it needs quality raw materials. Also, the preparation of raw materials for this process, such as agglomeration, coking and sintering, imposes high costs on the steel industry the direct reduction process is one of the new methods for iron production and in some cases, iron is produced without lumps. The direct reduction of iron oxides by carbon has been extensively studied in recent decades.

The direct reduced iron process is such that it usually contains more than 90% of metallic iron which tends to combine with oxygen to produce reduction iron, impurities such as oxygen must be removed from the iron ore by chemical reduction. There are different methods for producing iron most of this production is done by the blast furnace process and as a reducing agent after entering the furnace through processes and has carbon in the form of molten iron outside which eventually this molten iron is converted into steel. Iron production process by blast furnace in terms of production rate; it has high efficiency, but it needs quality raw materials. Also, the preparation of raw materials for this process, such as agglomeration, coking and sintering, imposes high costs on the steel industry the direct reduction process is one of the new methods for iron production and in some cases, iron is produced without lumps. The direct reduction of iron oxides by carbon has been extensively studied in recent decades.

Where Is Reduced Iron Produced?

The site of production of reduced iron varies, and the ores from which iron is extracted are mostly in the form of iron oxides, which are associated with 2 to 20% of impurities. These impurities are separated from the iron in the furnace and removed as pulp, and the refined and concentrated ore enters the furnace in the form of powder or fine granules. The direct reduction process at temperatures below the melting point temperature removes the oxygen in the iron ore and makes its structure spongy porous. Direct reduction reactions usually take place below the melting point of about 820 ° C, but in a blast furnace due to the high heat capacity of the product coke is molten. On the other hand, the dissolution of carbon in coke results in the production of crude cast iron with a high carbon content, which requires more energy in the steelmaking stage. Resuscitation is performed in direct resuscitation methods, such as in the abdomen of a high furnace, and the resuscitation gas acts on iron oxide and reduces it in several steps and iron oxide in this method is in the form of porous pellets to be able to pass the reducing gas.

The site of production of reduced iron varies, and the ores from which iron is extracted are mostly in the form of iron oxides, which are associated with 2 to 20% of impurities. These impurities are separated from the iron in the furnace and removed as pulp, and the refined and concentrated ore enters the furnace in the form of powder or fine granules. The direct reduction process at temperatures below the melting point temperature removes the oxygen in the iron ore and makes its structure spongy porous. Direct reduction reactions usually take place below the melting point of about 820 ° C, but in a blast furnace due to the high heat capacity of the product coke is molten. On the other hand, the dissolution of carbon in coke results in the production of crude cast iron with a high carbon content, which requires more energy in the steelmaking stage. Resuscitation is performed in direct resuscitation methods, such as in the abdomen of a high furnace, and the resuscitation gas acts on iron oxide and reduces it in several steps and iron oxide in this method is in the form of porous pellets to be able to pass the reducing gas.

Wonderful Direct Reduced Iron to Order

Wonderful direct reduced iron to Order is easily possible and distributors have been able to use their experience and measures to provide a useful and improved relationship and conditions between buyers and domestic and foreign markets and this in turn to economic prosperity and exports. The country has great help and has been able to play a significant role in improving the living conditions of the people until today, and the direct reduced iron price is very appropriate. Immediate ordering of iron reduction is possible for all people and they can get the product they need by visiting and contacting reputable centres. Today, the distribution center provides this product to customers in various ways, in general or in part, which is very well received due to its quality. It should be noted that in order to find out the existing conditions for the sale of bulk can be taken into action in various ways, we suggest that these loved ones visit this site and thus make their purchase efficiently. The most important factor in wholesale sales is the appropriate price and quality with the wholesale purchase the price includes good discounts for the customer.

Wonderful direct reduced iron to Order is easily possible and distributors have been able to use their experience and measures to provide a useful and improved relationship and conditions between buyers and domestic and foreign markets and this in turn to economic prosperity and exports. The country has great help and has been able to play a significant role in improving the living conditions of the people until today, and the direct reduced iron price is very appropriate. Immediate ordering of iron reduction is possible for all people and they can get the product they need by visiting and contacting reputable centres. Today, the distribution center provides this product to customers in various ways, in general or in part, which is very well received due to its quality. It should be noted that in order to find out the existing conditions for the sale of bulk can be taken into action in various ways, we suggest that these loved ones visit this site and thus make their purchase efficiently. The most important factor in wholesale sales is the appropriate price and quality with the wholesale purchase the price includes good discounts for the customer.

Your comment submitted.