CDRI sponge iron is a valuable material that has a wide range of applications across various industries.

Understanding its properties, production process, and benefits can help potential buyers make an informed decision when purchasing this essential material.

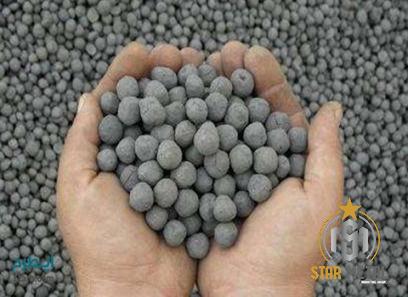

What is CDRI sponge iron? CDRI sponge iron, also known as direct-reduced iron, is a high-quality metallic product derived from iron ore.

t is produced through the reduction of iron oxide, primarily in the form of pellets or lumps, in a solid state at relatively low temperatures.

This process involves the removal of oxygen from the iron ore, resulting in a highly pure form of iron with a sponge-like structure.

.

Production Process

Production Process

The production of CDRI sponge iron typically begins with the selection of high-quality iron ore, which is then processed into pellets or lumps of the desired size.

These iron ore pellets are then fed into a rotary kiln or a fluidized bed reactor, where they are subjected to a controlled reduction process at temperatures ranging from 800°C to 1050°C. During the reduction process, a reducing agent such as natural gas or coal is injected into the kiln or reactor, which reacts with the iron oxide in the pellets to remove the oxygen content.

This reduction reaction leads to the formation of metallic iron particles with a high iron content of approximately 90-95%.

Once the reduction process is complete, the sponge iron product is cooled and discharged from the kiln or reactor.

The resulting CDRI sponge iron can be further processed and used in a variety of applications across different industries.

..

Applications of CDRI Sponge Iron

Applications of CDRI Sponge Iron

CDRI sponge iron finds wide application across various industries due to its high purity and unique properties.

Some of the key industries that utilize CDRI sponge iron include: 1. Steelmaking: CDRI sponge iron is a crucial raw material in the steelmaking process, where it is used to produce high-quality steel with superior mechanical properties.

2. Foundry Industry: CDRI sponge iron is widely used in the foundry industry to produce cast iron and other metal components with improved strength and durability.

3. Chemical Industry: CDRI sponge iron is utilized in the chemical industry for the production of catalysts, pigments, and various chemical compounds.

4. Automotive Industry: CDRI sponge iron is an essential material in the automotive industry, where it is used to manufacture engine parts, chassis components, and other critical automotive components.

…

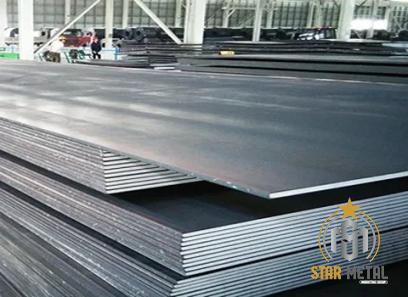

In the construction industry, CDRI sponge iron plays a vital role in the production of structural steel, reinforcing bars, and other building materials.

In the construction industry, CDRI sponge iron plays a vital role in the production of structural steel, reinforcing bars, and other building materials.

The versatility and structural integrity of CDRI sponge iron make it an ideal choice for constructing high-rise buildings, bridges, and infrastructure projects.

By using CDRI sponge iron in construction applications, builders and contractors can ensure the durability, stability, and longevity of their structures while minimizing maintenance costs and environmental impact.

In summary, CDRI sponge iron is a versatile and valuable material that offers a wide range of benefits across various industries.

Its high purity, low impurity levels, energy efficiency, and customizable properties make it a preferred choice for steelmaking, foundry, chemical, automotive, and construction applications.

By understanding the production process, benefits, and applications of CDRI sponge iron, potential buyers can make informed decisions when purchasing this essential material to meet their specific needs and requirements.

Your comment submitted.