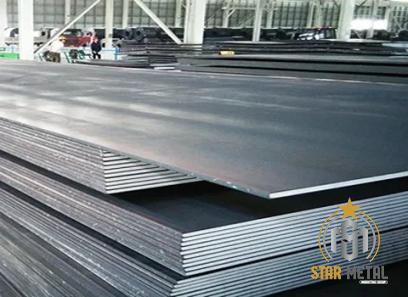

Sheet metal is a versatile material that finds widespread use in various industries and applications.

When it comes to selecting the right type of sheet metal for your project, the 4×8 sheet metal 3/16 stands out as a popular choice due to its dimensions and thickness.

In this comprehensive guide, we will walk you through the key features, benefits, and considerations of the 4×8 sheet metal 3/16, helping you make an informed decision for your next project.

.

To maximize the value of the 4×8 sheet metal 3/16, consider the following tips when handling and installing the material:

To maximize the value of the 4×8 sheet metal 3/16, consider the following tips when handling and installing the material:

1. Preparation: Before starting your project, ensure that you have the necessary tools and equipment on hand, including safety gear such as gloves, goggles, and a face mask.

Measure and mark the sheet metal according to your design specifications, taking into account any cutting or bending requirements.

2. Cutting: Use a metal shear, jigsaw, or circular saw with a metal-cutting blade to cut the sheet metal to size.

Take care to make precise cuts and avoid excessive force, as this can cause distortion or damage to the material.

Wear ear protection to reduce noise levels during cutting.

..

3. Bending: To create bends or folds in the sheet metal, use a metal brake, bending machine, or hammer and dolly.

3. Bending: To create bends or folds in the sheet metal, use a metal brake, bending machine, or hammer and dolly.

Make sure to follow the proper bending techniques to achieve clean and accurate results.

Apply even pressure along the bend line to avoid creases or deformations in the material.

4. Welding: If welding is required for your project, use a MIG or TIG welder along with the appropriate welding wire or rod for the type of metal being used.

Follow welding safety procedures and guidelines to ensure a strong and secure bond between the metal pieces.

5. Finishing: Once the sheet metal is cut, bent, and welded into place, you can apply a finish or coating to enhance its appearance and protect it from corrosion or damage.

Consider options such as painting, powder coating, or galvanizing to achieve the desired aesthetic and functional qualities.

…

By following these tips and techniques, you can make the most of the 4×8 sheet metal 3/16 and ensure a successful outcome for your projects.

By following these tips and techniques, you can make the most of the 4×8 sheet metal 3/16 and ensure a successful outcome for your projects.

With its exceptional price, durability, versatility, and ease of installation, this sheet metal offers a cost-effective solution that meets your needs and exceeds your expectations.

Whether you are a professional contractor, fabricator, or DIY enthusiast, the 4×8 sheet metal 3/16 provides a reliable and efficient option for a wide range of applications.

Invest in this exceptional sheet metal today and experience the benefits it brings to your projects in terms of quality, performance, and value.

Your comment submitted.